Application

- Unit power: 225 MW

- Steam parameters:

- SH: 15.95MPa (2,313 PSI)/540°C

- RH: 2.43MPa (352 PSI)/540°C

- Fuel: hard coal

- Boiler capacity: 650 t/h

- OFA dampers

- Ovation DCS

- AGAM system provided by Bonnenberg + Drescher

Customer

EDF Poland, Rybnik Power Station (1 775 MW installed capacity, over 10 TWh annual energy production), Unit 4

Goals

- Increase efficiency by 0.2%

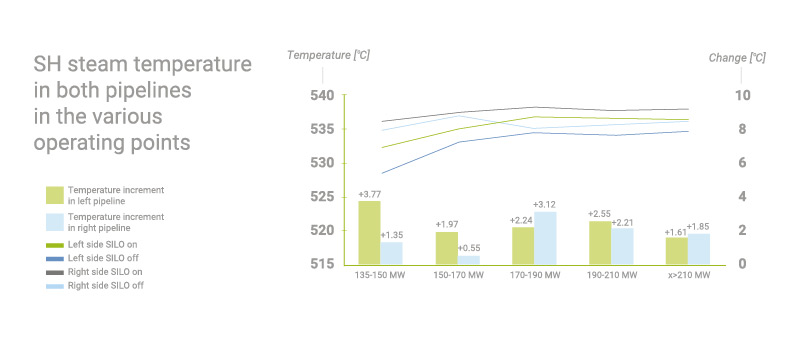

- Keep the design values of SH and RH steam temperatures (540°C)

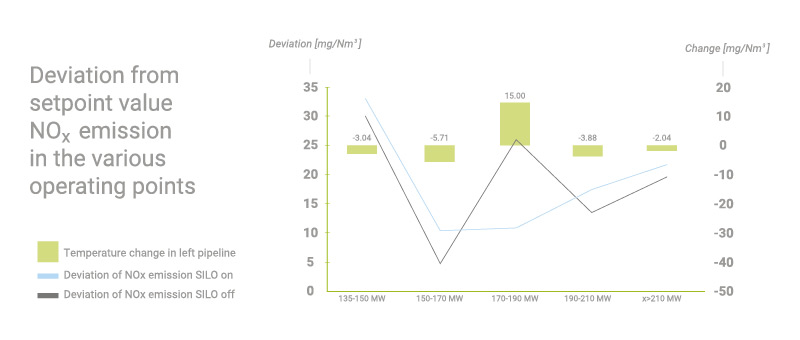

- Minimize NOx setpoint deviation (±20 mg/Nm3)

- Keep CO emission below 100 mg/Nm3

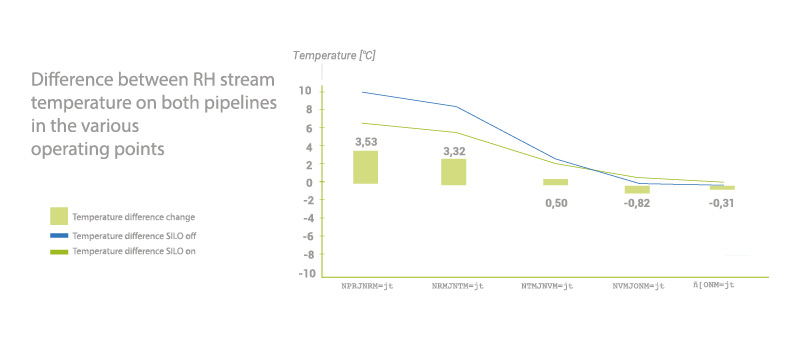

- Symmetrize process parameters

Results

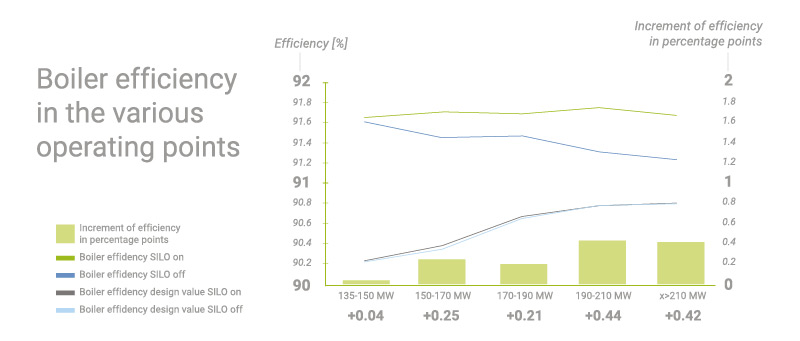

- 0.27% average increase of boiler efficiency

- Reduction of CO2 emission by 4380 t/y ($21 500 savings)

- Reduction of coal consumption by 1565 t/y ($135 000 savings)

- Reduction of ammonia usage by 665 t/y ($130 000 savings)

- Total operational costs reduction of $286 500 per year

Analysis

SILO can effectively improve process parameters. As a consequence, this resulted in an increase in boiler efficiency. At partial loads, when available adjustment range was small, the optimizer did not have the opportunity to significantly change performance of the boiler, but when the range of available control signals increased, SILO could very quickly improve its performance. At full unit power the efficiency increase reached values above 0.4 percentage points.

In the entire power range SILO was able to improve adherence to design values of superheated steam temperature. When the temperature most deviated from the design value SILO strongly affected the process to improve it. This shows the ability of the optimizer to change priorities of optimization and the ability to adapt to actual operating conditions.

SILO developed an improvement in temperature symmetry. During the boiler operation at partial loads there was a significant asymmetry of temperatures. By changing the values of control signals SILO reduced the difference between temperatures in both pipelines. When the temperature symmetry was improved the optimizer could change its optimization priorities.

SILO was set to reduce the occurrence of NOx setpoint deviations of 20 mg/Nm3 and prevent from deviations above 40 mg/Nm3, which was successfully achieved. If NOx emissions met the requirements, SILO focused on improving the values of other parameters. So when the NOx emissions were within the limits the optimizer allowed low variations of this value.

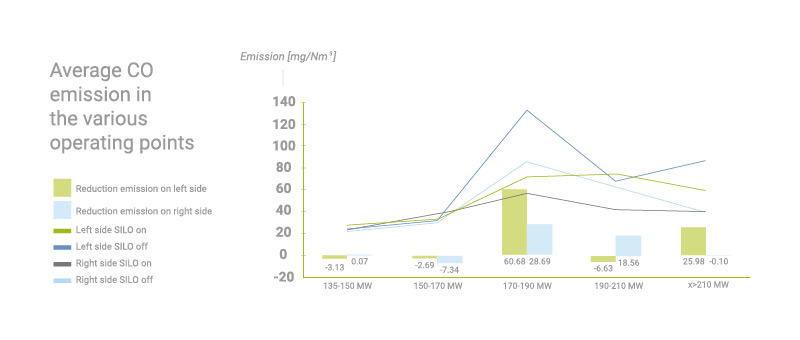

The aim of the optimizer for CO emissions was to reduce occurrence of values above 100 mg/Nm3 and prevent from emission higher than 200 mg/Nm3. Both goals were achieved by SILO. Additionally, emissions of CO were reduced and significantly stabilized. Such behavior demonstrates greater stability of the combustion process under control of SILO.

Summary

After SILO implementation at Unit 4 an increase in boiler efficiency throughout the whole operating range was achieved. During long-term operation it amounted to an average of about 0.27% and resulted in coal consumption reduction of about 1565 t/y and reduction of CO2 emissions by 4380 t/y. SILO also developed a greater process parameters symmetry between right and left side of the boiler. Better equalization of these values improves stability of the process and has a positive impact on lifecycle of the devices. Thanks to stabilization and long-term reduction of NOx emissions SILO provided additional operational savings associated with ammonia usage reduction of about 665 t/y. Combustion process optimization resulted in substantial CO emissions reduction.